Our Geopoly team of skilled and experienced Technicians are committed to provide efficient and reliable installations service. Installations require detailed planning and co-ordination with the Project Owners, Consultants, Engineers and Contractors to ensure special attention and timely completion of their lining projects.

We provide professional and comprehensive advise on the proposed Pond, Cell, Tank or Site preparations including advise on earthworks, perimeter anchor trench preparation, sub grade, anti-floatation sub-soil piping systems and other project preparations details.

HDPE geomembrane liners can be installed quickly when compared to concrete, clay or other spray-on membrane liners. Geomembrane liners are easily unrolled and layed over the prepared surfaces and seamed by our trained technicians or authorized applicators and installers. Each panel deployed and seamed is recorded to indicate roll identity, date, time, equipment, supervisor and other details.

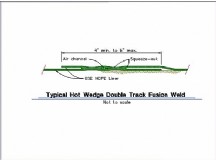

HDPE geomembrane liners are welded by Fusion Weld using the DEMTECH Hot Wedge Welding machine for long linear welds. The DEMTECH Wedge Welder creates a fusion weld by heating the overlapped liner surfaces, with a pair of nip rollers pressing the sheets together while in molten state to result in a permanent bond.

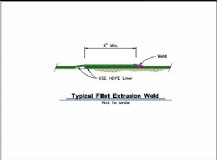

Specific areas such as sumps, pipe penetrations, concrete structures, fittings and accessories shall require special installations techniques. Non-linear seams, roll ends, pipe penetrations, sumps, patches, corners or anywhere it is impractical to use a Wedge Welder are welded by Extrusion Weld using the DEMTECH Extrusion Gun. The DEMTECH Extruder converts HDPE welding rod feeds into an extrudate that binds the weld area.

Folds at corners and edges are neatly trimmed, overlapped and welded by the extrusion weld. Similarly, any minor cuts, punctures or repairs are initially tack welded or patched by a DEMTECH Hot Air Tool Kit and is then further reinforced by the extrusion weld.

The Installation Quality Assurance Plan include routine trial welds at

the beginning of each work day, where small samples of liner are welded

and tested for peel and shear. Trial welds assist to check and adjust

welding equipment heating temperatures, roller pressure and variable

speed controls. Once calibrated, the installation commences.

Destructive seam testing involves cutting out a section of the seam and tested on site. Weld samples are cut into test strips using the DEMTECH Bone-Cutter. The overlapping welded test strips are tensioned in opposite directions to observe weld strength for shear and peeling using the DEMTECH Tensiometer.

Destructive seam testing involves cutting out a section of the seam and tested on site. Weld samples are cut into test strips using the DEMTECH Bone-Cutter. The overlapping welded test strips are tensioned in opposite directions to observe weld strength for shear and peeling using the DEMTECH Tensiometer.

Random non-destructive

air channel or vacuum tests may be conducted on the Double-track fusion

or extrusion welded seams using the DEMTECH Manometer or the DEMTECH V-Plate Vacuum Box Tester.